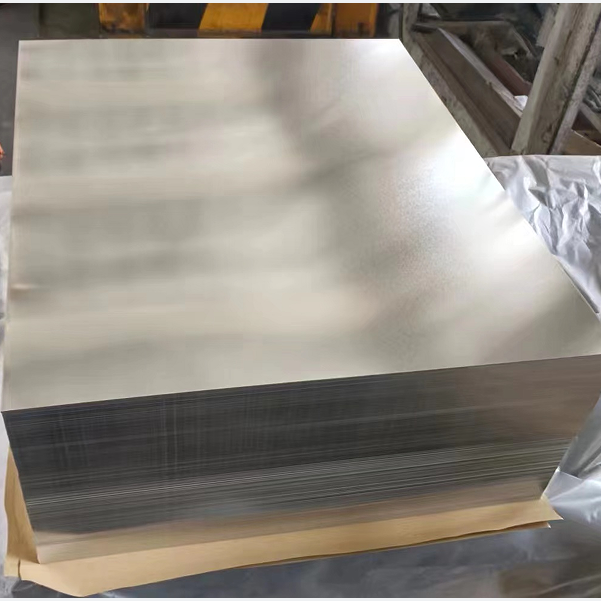

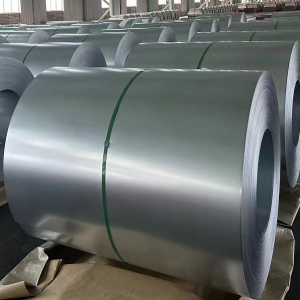

Cold Rolled Steel Tinplate Electrolytic Tinplate Sheet

Electrolytic tinplate inotonhora yakakungurutswa kabhoni simbi ndiro yakavharwa nerata yakachena pamativi ese, inyanzvi yekugadzira tekinoroji, tekinoroji, maitiro akareba ekugadzira, zvemhando yepamusoro zvinodiwa uye kugadzira zvigadzirwa zvakaoma.

Electrolytic tinplate sheet haingove nesimba rakakwirira, kuumbwa kwakanaka, kusimba kwekuora, kusimba kwakasimba, kutaridzika kupenya, nezvimwewo, asi zvakare ine mavara akanaka ekudhinda, pamwe nerayi retani harina chepfu, saka electroplated tin ndiro inoshandiswa zvakanyanya mukugadzira. indasitiri yechikafu uye kugadzirwa kweakasiyana emidziyo, zvidhindo zvigadzirwa, zvekurongedza zvinhu uye mamwe asiri echikafu indasitiri.

Inodzivirira kupisa

Recyclable

Easy processing

Iyo tin layer inogona kuvandudza zvakanyanya kudziya kwepamusoro-tembiricha yeti-plated ndiro.Tichifunga kuti akawanda maapplication anoda kushandiswa kwenzvimbo dzepamusoro-tembiricha, tin-plated mapepa saka anoshandiswa zvakanyanya.

Cold rolled steel tinplate ine yepamusoro processability.Inogona kuchinjika kune dzakasiyana siyana dzekuumba nzira dzekugadzirisa, sekuveura, laminating, kuumba uye zvichingodaro.Izvi zvinoita kuti zvishandiswe zvakanyanya muindasitiri yemwenje.

Tin-plated sheet haina chepfu, haina kusvibisa uye ine yakanaka kudzokorodza.Nokudaro zvakare chinhu chakanaka maererano nekuchengetedzwa kwezvakatipoteredza.

Tinplate electrolytic inoshandisa electroplating kuderedza kukora kwezvinhu zvesimbi.Iyo tin layer inogona kudzivirira zvinobudirira zvinhu zvesimbi kubva pamhepo kana mvura oxidation inotungamira mukuora.

Application

1. Munda wekurongedza chikafu

Tinplate mucoil ndechimwe chezvinhu zvakanyanya kushandiswa zvekurongedza chikafu.Nekuti tin layer mundiro yakapfekwa inogona kuita basa rekuparadzanisa mhepo, chiedza nemvura, kuve nechokwadi chekuti chikafu hachiparare uye kunhuhwirira.Mukuwedzera, iyo tin layer inogona zvakare kuvandudza kusimba kwepakeji kuve nechokwadi chekuchengetedza chikafu.

2. Indasitiri yemagetsi

Tinplate sheet ine yakakosha application muindasitiri yemagetsi.Inoshandiswa zvakanyanya mukugadzirwa kwema capacitors, mabhatiri uye zvimwe zvigadzirwa zvemagetsi.Nekuti iyo tin layer inogona kuwedzera conductivity uye corrosion kuramba kweti-plated ndiro uye inogona kuvandudza kutaridzika kwemidziyo.

3. Munda wekugadzira motokari

Cold rolled steel tinplate sheet inoshandiswawo zvakanyanya mukugadzira mota.Muindasitiri yemotokari, ndiro yerata inowanzoshandiswa kugadzira nhengo dzemuviri, matangi emafuta, pombi dzekupedza simba nezvimwe zvikamu.Inogona kuita basa mukudzivirira ngura, kuvharidzira ruzha uye kuderedza ruzha.

Kukura Trend

Iyo tin-plated simbi yekugadzira maitiro yakamisikidzwa, asi imwechete process link ichiri mukuenderera mberi nekuvandudza uye kusimudzira.Ikozvino tin-plated simbi yekugadzira ndiro yekugadzira tekinoroji yekuvandudza tekinoroji inoita kunge:

1. Kushandiswa kwesimbi kunze kwekunatsa kwechoto uye yakakura-yakakura inoramba ichikanda teknolojia, kuti uwane yunifomu yakagadzirwa, yakanaka yesimbi yesimbi, kuitira kuti ienderane kune zvakasiyana-siyana zvekugadzirisa zvinoda.

2. Kushandiswa kwechipiri inotonhora yekukunguruka uye inoenderera mberi annealing tekinoroji, kugadzirwa kwe0.15 ~ 0.18mm yeplate yepakutanga, uye kuoma kwayo kwakanyanya.

3. Nyatsoteerera kune pre-plating uye post-plating kurapwa, uchishandisa musanganiswa we-soft-melt treatment, nekugadzirwa kweA-grade, uye K-grade tin-plated steel plate.

4. Wedzera kugovera kweimwe yesimbi yekuputira nesimbi yakagadzirwa.

5. High-speed uye automated kuongorora uye kutonga kwekushanda mutsara, kugadzirwa kwekukurumidza kusvika 600 ~ 760m / min.