SPCCndiro yesimbi

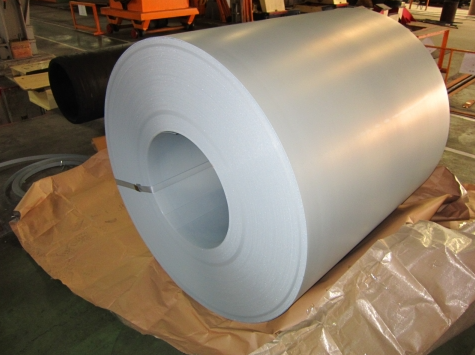

SPCC simbi ndiro is ainotonhora yakakungurutswa kabhoni simbi ndiroinotsanangurwa muJapan Industrial Standard (jis g 3141).Zita rayo rakazara i "simbi ndiro inotonhora yakakungurutswa yekutengesa mhando", apo spcc inomiririra hunhu uye mashandisirwo eiyi ndiro yesimbi: s inomiririra simbi., p zvinoreva plate flat, c zvinoreva giredhi rekutengesa, uye yekupedzisira c inoreva kutonhora kukunguruka.Iri ndiro ndiro ndiro yakaderera kabhoni simbi inowanzo shandiswa kugadzira zvikamu zvemafiriji matsva, mafiriji akadzikiswa kana mabhandi ekutakurisa motokari.Iyi ndiro yesimbi ine yakanakisa kuumba uye kutsika zvivakwa, uye inogona kugadziriswa nekudzika kutonhora kutsika.Nekuda kwekuderera kwayo kabhoni, ine hurombo hwemagetsi zvimiro asi ine yakanaka yepurasitiki, ichiita kuti ive nyore uye nyore kugadzira muhukuru hwakasiyana.Kunyangwe spcc simbi ndiro isingakodzeri maapplication anoda simba repamusoro, ichiri kushandiswa zvakanyanya mumaindasitiri mazhinji akadai semidziyo yemumba nemotokari.Panguva imwecheteyo, chinyorwa ichi chinewo yakanakisa corrosion kuramba uye inoshandiswa zvakanyanya muzviitiko zvine zvakakwirira zvinodiwa.

Kurapa kwepamusoro kwe spcc steel plate kunogona kuitwa nenzira dzakawanda.Hedzino dzimwe nzira dzakajairika:

Mechanical cleaning: Shandisa maturusi akaita sewaya mabhurashi kana sandpaper kukwenenzvera nekusukurudza pamusoro kubvisa tsvina yakaita ngura neoiri.

Kemikari kurapwa: kushandisa asidhi, alkali kana mamwe makemikari reagents kunyungudutsa kana kushandura maokisi epamusoro kana zvimwe zvitsvina kuita zvinhu zvinocheneswa kuzadzisa chinangwa chekuchenesa pamusoro.

Electroplating kurapwa: Metal plating inoitwa pamusoro pesimbi ndiro kuburikidza ne electrolysis kuti ibudise danda resimbi rinodzivirira kuti rivandudze kusaita ngura uye chitarisiko.

Coating treatment: Psaya mavara akasiyana ependi pamusoro pespcc simbi ndiro kuti itambe anti-corrosion uye kushongedza mabasa.

Nzira dzakasiyana dzekurapa dzepamusoro dzakakodzera kune dzakasiyana maindasitiri zvinodiwa.Kusarudza nzira yakakodzera yekubata pamusoro pe spcc simbi ndiro zvinoenderana nemamiriro chaiwo anogona kuwedzera hupenyu hwayo hwesevhisi uye kuchengetedza yakanakisa mechanic zvivakwa.

SECC simbi ndiro

Zita rakazara reSECC rinoti Steel, Electrolytic Zinc-coated, Cold Rolled Steel Coil, inova ndiro yesimbi inogezwa nemagetsi mushure mekutonhora.Iyo yepamusoro inogadziriswa electrolytically kuti ive nani anti-corrosion performance uye aesthetics.Inowanzo shandiswa kugadzira zvigadzirwa zvine yakaderera anti-corrosion kuita uye zvekushongedza zvinodiwa, senge midziyo yemumba, midziyo yemidziyo, nezvimwe.

SECC galvanizing nzira:

Kupisa Yakanyudzwa Galvanized Coil: Kupisa-dip galvanizing mushonga unorwisa-corrosion unoumba zinc layer pamusoro pesimbi.Ndeko kunyudza ndiro dzesimbi kana zvidimbu zvesimbi mumvura yakanyungudutswa yezinki iyo inotaridzwa kusvika kune tembiricha yakakodzera (kazhinji 450-480 madhigirii celsius), uye kugadzira yakakora uye yakakora zinc-iron alloy coating pamusoro pezvikamu zvesimbi kuburikidza nekuita.Chengetedza zvikamu zvesimbi kubva pakuora.Kuenzaniswa neelectrolytic galvanizing, hot-dip galvanizing ine yakakwira corrosion kuramba uye hupenyu hurefu hwesevhisi, uye inowanzo shandiswa kugadzira zvigadzirwa zvakakosha senge mahombe maumbirwo, ngarava, mabhiriji, uye michina yekugadzira magetsi.

Inoenderera galvanizing nzira: Mashizha esimbi akakungurutswa anoramba akanyudzwa mubhavhu replating rine zinc yakanyungudika.

Plate galvanizing nzira: Iyo simbi yakachekwa ndiro inonyudzwa mubhavhu rekugezera, uye pachave ne zinc spatter mushure mekuputirwa.

Electroplating nzira: electrochemical plating.Pane zinc sulfate solution muplating tank, ine zingi seanode uye yekutanga simbi ndiro secathode.

SPCC vs SECC

SECC galvanized steel sheet uye SPCC inotonhora yakakungurutswa simbi pepa zvinhu zviviri zvakasiyana.Pakati pazvo, SECC inoreva electrolytically galvanized inotonhora-yakakungurutswa simbi mashiti, nepo SPCC iri yepasirese inotonhora-yakakungurutswa simbi sheet standard.

Misiyano yavo mikuru ndeiyi:

Zvimiro zvemuviri: SECC ine zinc coating uye ine zvirinani corrosion resistance;SPCC haina anti-corrosion layer.Naizvozvo, SECC yakasimba kupfuura SPCC uye inodzivirira ngura uye ngura.

Kurapa kwepamusoro: SECC yakapinda electrolytic galvanizing uye mamwe maitiro ekurapa, uye ine imwe dhigirii yekushongedza uye aesthetics;nepo SPCC inoshandisa inotonhora yekutenderedza maitiro pasina kurapwa kwepamusoro.

Kushandiswa kwakasiyana: SECC inowanzo shandiswa kugadzira zvikamu kana casings muminda yemidziyo yemagetsi, mota, uye midziyo yemumba, nepo SPCC ichishandiswa zvakanyanya mumaindasitiri akadai sekuvaka, kugadzira, uye kurongedza.

Muchidimbu, kunyangwe ese ari maviri anotonhora-akakungurutswa simbi mahwendefa maererano nemaitiro ezvikamu, pane misiyano yakakura mumaitiro avo e-anti-corrosion, kurapwa kwepamusoro uye kushandiswa.Kusarudzwa kweSECC kana SPCC simbi ndiro inofanira kusarudzwa zvichienderana nemamiriro ezvinhu chaiwo, tichifunga nezvezvinhu zvakasiyana-siyana zvakadai sekushandiswa kwechigadzirwa chiri kugadzirwa, zvakatipoteredza uye zvinodiwa chaizvo, uye kusarudza zvinhu zvakakodzera.

Nguva yekutumira: Nov-06-2023